Boiler Mountings and Accessories

The necessary devices installed or mounted for the safety of boiler and its control are called boiler mountings, The devices which are installed in the boiler for their efficient operation and smooth working are called boiler accessories.

Boiler mountings form an integral part of the boiler. They are necessarily required to be fitted on the boiler shell in accordance with Indian boiler regulation (IBR) act 1923. These are as follows :

Boiler mountings for safety :

- Two water level indicators – 2

- Two safety valves.

- Combined high steam and low water safety valve

- Fusible plug.

Boiler mountings for control :

- Pressure gauge.

- Junction or stop valve.

- Feed check valve.

- Blow – off cock.

- Man hole and mud hole.

Boiler accessories are not essential from IBR point of view since these are provided only for efficient operation. These are :

- Water heating devices.

- Water feeding devices.

- Superheater.

- Economiser.

- Air preheater

Boiler Mountings and Accessories :

The required boiler mountings are being discussed below :

Water Level Indicator :

- Water level indicators are two in numbers. These are fitted in front of the boiler and its function is to check the level of water inside the boiler.

- In case the water level falls below the minimum level, the boiler attendant must feed either more water to the boiler or stop firing the boiler. The sketch of a water level indicator is shown in Figure A.

- AD represents the front plate of the boiler in which the water level and steam is shown. It consists of a strong glass tube (GT) whose ends pass through the stuffing boxes (SB) in hollow gun metal casting having flanges (F – F) for bolting to the boiler plate. The upper flange is bolted to the steam space and lower flange is bolted to the water space.

- Water cock (WC) and the steam cock (SC) control the passages between the boiler and the glass tube. When these passages are open, the handle of these cocks are vertical as shown.

- Cock (C) is the drain cock which is used at frequent intervals to blow out any sediments and deposits. It ensures that the steam and water passages are clear. Under closed position the drain cock is kept in vertical position.

|

| Figure A |

- Two balls (B – B) are placed at the junction of gun metal tubes. These balls help to close down the passages of steam and water from the boiler shell in case the glass tubes breaks. Under normal operating conditions the balls are kept as shown in Figure A.

- In case the glass tube breaks, the rush of water in bottom passage carries the ball into the position shown by dotted circle and shut-off the water supply and similarly the rush of steam displaces the upper ball in position shown by dotted lines to shut-off of the steam supply. The boiler operator then closed the water and steam cocks and can safely replace the glass tube.

- The stuffing box consist of heat resistance rubber packings to prevent the leakage of steam and water.

- The boiler operator is protected from the flying glass pieces in the event the glass tube breaks by providing a thick toughened glass cover around the glass tube.

Pressure Gauge :

- Pressure gauge helps in recording the pressure of steam in the boiler. It is fitted in front of the boiler so that the boiler attendant can conveniently read it and keep the record of pressure of steam developed.

- The commonly used pressure gauge is Bourdon’s pressure gauge shown in Figure B. The pressure recorded by this gauge is the pressure above atmospheric i.e. it records the gauge pressure.

|

| Figure C |

- Bourdon pressure gauge consists of an elliptical spring tube (E), called Bourdon tube which is solid drawn out of the special quality bronze.

- It’s end – X is plugged and the other end Z is secured firmly to a hollow block (H) threaded at the bottom where it is connected to a siphon pipe (S).

- The other end of the siphon pipe is connected to steam space of the boiler. The siphon pipe contains condensed water which also fills the Bourdon tube.

- The steam pressure which acts on the water is finally transmitted to the Bourdon tube and it tends to make its section circular.

- The tube being fixed at the end X moves outwards. The movement of X is proportional to the difference in internal and external pressures on the tube.

- However, the movement of end – X is magnified by a mechanism consisting of link (L). toothing section (T) which is pivoted at Y and gears with pinion (A).

- The pinion is fixed to a spindle which carries the pointer B, the position of which on the calibrated dial reads the steam pressure in gauge in the boiler.

- A plug (P) is provided for cleaning the siphon tube. The siphon is filled with cold water to prevent the hot steam entering into the Bourdon tube and thus the spring tube remains comparatively cool, otherwise, the overheating of spring tube will affect the accuracy of the pressure gauge.

Safety Valves :

- It is provided on the top of boiler in order to safeguard the boiler from bursting due to excessive boiler pressure above the designed pressure.

- The function of a safety valve is to allow the steam to escape to the atmosphere if the pressure in the boiler exceeds the designed pressure. As a result the steam pressure in the boiler decreases. There are four types of safety valves :

- Lever safety valve.

- Dead weight safety valve.

- Spring loaded safety valve.

- High steam and low water safety valve.

(1) Lever safety valve :

- This is shown in Figure C. It consists of a block on which the valve seat is screwed. On the seat the valve rests.

- The valve and valve seat are made of bronze material. The block is connected to steam boiler with the help of flange.

- The downward force on the valve is transmitted through the strut. The lever rests on the bridges fixed to the block and at one end of the lever a weight is attached and the other end is hinged.

- The required weight is determined to keep the valve closed up to the designed steam pressure. If the steam exceeds, the valve is lifted from the seat and the steam escapes to the surroundings.

- A dead weight safety valve made by M / s Hopkinson and Co. is shown in Figure D. These are suitable only for stationary boilers.

- It consists of the valve (V) which rests on the valve seat (S) which is rigidly secured at the top of the vertical steel pipe (P) by means of a ring and screws .

- The ring has a feather (F) cast on it. It helps to guide the motion of the valve in vertical direction only Vertical pipe has a flange (FL) at the bottom for bolting to a mounting block connected to boiler shells.

- At the top of the valve, a weight carrier (WC) is suspended on which the weights (W) are carried. A cast iron cover (C) is fitted over the weights and the weight carrier

- The weights required on the weight carrier are calculated based on the maximum pressure required in the boiler shell.

- The steam pressure force is balanced by the load on the valve made up of weight of the weight carrier, its covers, weight of the valve itself and the weights.

- If the steam pressure exceeds the limiting pressure, the valve lifts from its seat and it allows the steam to escape through the discharge casing (DC) to waste pipe till the steam pressure falls to its limiting pressure A drain (D) is provided to drain out any condensed steam in the discharge casing.

|

| Figure D |

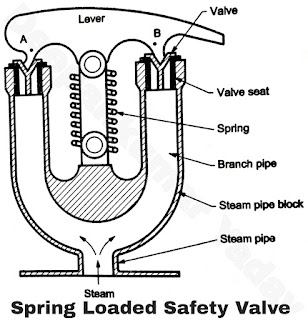

Spring loaded safety valve :

- This type of safety valve is shown in Figure E. The main steam pipe is flanged to boiler and the steam pipe splits into two pipes.

- The branch pipes have their usual arrangements of a valve seat and the valve. The valve is kept on its seat with the help of spring force.

- One end of the spring is connected to the lever and the other to the steam pipe block. The lever has two pivots at A and B. Pivot A is pin joined while B is fixed to the lever. The steam can be released by operating the lever.

|

| Figure E |

- Boilers like Lancashire and Cornish are provided with a safety from high pressure in case it exceeds the designed pressure and also the safety from overheating in case the water level falls below the minimum level.

- A high steam and low water safety valve introduced by Hopkinsons is shown in Figure F .

- It consists of lever A which is hung inside the boiler shell and it is hinged at point C. One end of the lever carries a balance weight and the other end carries an carthen float immersed in water ,

- The balance weights are kept in such a way that the knife edge of the lever just touches the projection when the float just dips into water .

- It also consists of two valves. One is the main valve V1 which rests on its seat. The edge of central opening in the valve V1 forms the seat for the hemispherical valve V, and the end of valve rod carries a weight.

- When the water level falls and float is sufficiently uncovered from water, the weight of the float increases and no longer it is balanced by the balance weights. Consequently, the float end of the lever will descend and causes a swing in the lever A

- The knife edge projections of the lever will come in contact with collar fixed on the valve rod and when the lever swings, the valve rod is pushed up. It also pushes up the hemispherical valve V2 and the steam leaks through the gaps provided with a loud noise. This acts as a warning to the boiler attendant.

- When the hemispherical valve is closed, the main valve V1 acts as an ordinary lever safety valve and it guards against the high pressure in the boiler.

- The valve V1 is held in position partly by the weight on the rod of valve V2 and partly by the loaded lever above the valve casing,

- When the steam pressure exceeds the limiting working pressure, the main valve V1 along with valve V2 lifts up and the steam leaks out through the discharge duct.

- The valve placed directly on a boiler in order to regulate the steam supply from boiler to steam pipe is called the junction valve and the valve used to regulate the steam supply from the steam pipe to the prime-mover (steam engine or steam turbine) is called the stop valve.

- The valve is usually placed near the prime-mover. The junction valves are also frequently called as stop valves.

- The constructional details of a steam stop valve is shown in Figure G when used as a junction valve. It consists of a valve chest (VC) made of cast iron.

- Valve chest has two flanges F1 and F2 at right angles to each other. Flange F1 is mounted at the top most position of the boiler shell through which steam enters into the stop valve from the boiler and the other flange F2 is connected to steam pipe for carrying steam from stop valve.

|

| Figure G |

- A gun metal valve seat (VS) is screwed in the valve chest with the aid of lugs (L) cast on its interior. The valve disc (VD) has a renewable disc seat (DS) screwed on it.

- The valve disc is connected to spindle (S) by a nut (N), the lower end of which comes in contact with the collar (C) on the lower end of the spindle. Such an arrangement allows the spindle to rotate within the valve disc but carries the valve dise along when the spindle is lowered or raised.

- The spindle passes through the gland (G) and stuffing box formed in the cover (C) of the body. The upper portions of the spindle has square threaded screw (SC) which passed through the nut (N) in a yoke (Y) carried by two pillars (P – P).

- The spindle is rotated by hand wheel (W). By turning the spindle with the help of hand wheel, the valve disc can be raised and the steam from the boiler passes to the steam pipe.

- Whenever desired, the valve disc can be lowered by rotating the spindle in opposite direction by hand wheel.

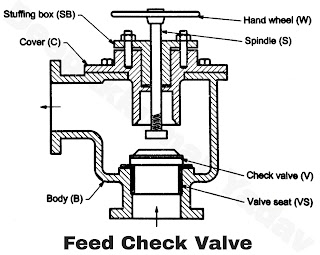

Feed Check Valve :

- The feed check valve is a non-return valve which permits the flow of water in one direction only and automatically prevents the back flow of water from the boiler when the feed water pump is either not working or in case of its failure.

- The feed check valve is fitted in the feed pipe of the boiler just below the working level of water in the boiler.

|

| Figure H |

- A commonly used feed check valve is shown in Figure H. It has check valve (V) whose lift is controlled by the lower end of the spindle (S). The check valve rests on its valve seat (VS).

- The check valve can be kept in closed position by pressing it down by the spindle operated by the hand wheel (W). A cover (C) is bolted to the body of the feed check valve and carries the assembly by stuffing box and the gland to prevent any leakage as shown in Figure H.

- Before starting the feed pump, the spindle is lifted from the valve with the help of hand wheel. When the feed pump is started, the check valve is subjected to boiler pressure from the top and by feed water pressure from the bottom.

- The valve is lifted from its seat since the feed water pressure is more than boiler pressure. When the feed pump is stopped, the valve falls automatically on its seat due to downward thrust of the boiler pressure and thus the reverse flow of water from boiler feed pipe is prevented.

Blow-Off-Cock :

- The blow off cock is directly fitted on the boiler at the bottom of water space in the boiler. It is used either to remove the mud and sediments, while the boiler is in operation or to remove the water when the boiler is subjected to inspection, repair or maintenance.

- A type of blow off cock is shown in Figure I. It consists of gun-metal conical plug (P) having a slot in it. This plug is placed accurately into the corresponding hole in the casing (C) which is packed with asbestos packing (AP) in the grooves of the plug.

- The shank (SH) of the plug valve (V) passes through the gland (G) and the stuffing box in the cover. The gland is provided to prevent the leakage of water at the shank.

- A set screw (S) provided at the bottom of the plug is used to force it off its seat if it is jammed. The plug is held down by a yoke (Y) and two studs not shown in Figure I.

- On top of the yoke, two vertical slots are provided for fixing the box spanner which is used for opening and closing the blow off cock.

|

| Figure I |

- The casing is provided with two flanges, one flange is connected to the boiler and the other flange is connected to a pipe to carry the discharge at a distance away from boiler

- In order to discharge water from the boiler, the plug is so rotated that the slot of the plug comes in line with the hole in casing. When it is required to stop the flow of water, plug is rotated till its solid part comes in line with the hole in casing.

Fusible Plug :

- The main function of the fusible plug is to extinguish fire when the water level in the boiler falls below a certain minimum level i.e. the danger level.

- The fusible plug is usually placed at the lowest most permissible water level over the combustion chamber or it is inserted at the fire box crown.

- The constructional details of a fusible plug is shown in Figure J. It consists of three plugs P, R and S.

- The hollow plug having hexagonal flanges (F) is screwed to the fire box crown plate (CP). The plug R is screwed to the plug P and the plug S is locked into plug R by a metal like tin or lead which has a low melting point. Plugs P and R are made up of gun metal, while the plug S is made up of copper.

- In normal working condition, water covers the fusible plug and remains cool. In case the water level falls below the danger levels, the fusible plug gets exposed to steam. This overheats the plug and the fusible metal having low melting point melts quickly. Due to this plug S falls.

- The opening so made allows the steam to rush on to the furnaces and extinguishes the fire or it gives warning to the boiler attendant that the crown of furnace is in danger of being overheated.

|

| Figure J |

- The ribs (RS) cast integral with the gun metal body (B) holds falling plug S and prevents it from falling into the combustion chamber. Before restarting the boiler, the fusible plug is replaced.

Manhole :

- This is provided at suitable position on the boiler shell so that the man can enter into boiler shell for its inspection, maintenance and repairs.

- This hole is usually made in elliptical shape of the size convenient for a man to enter through this hole. The opening is closed by a steam tight cover.

- Steam traps are used to collect and automatically drain away the water resulted from partial condensation of steam without steam to escape with this condensate.

- Flow of condensate in steam pipe is by gravity to the steam trap.

- This condensate from the steam is drained out through a valve when sufficiently high condensate is accumulated in the trap.

- The valve after draining the condensate is closed. It presses the leakage of steam from the trap.

Antipriming Pipe :

- An antipriming pipe is attached below the stop valve to avoid the water particles being carried away alongwith steam. It has a long pipe with closed ends of 1 m to 2 m length.

- The top side of pipe has perforations.

- When the stop valve is opened, initially the steam passes through the antipriming pipe and due to inertia effect the moisture of steam falls into the pipe and the steam with reduced moisture passes into the stop valve.