Pulverized Fuel Handling System

There are two methods of delivering the pulverized coal to the furnace as follows :

- Unit system.

- Bin or central system.

1. Unit system :

|

| Figure A |

- In case of unit system, each furnace of the plant is fired by its own pulveriser connected to burner while in case of bin system the coal is prepared in the central plant and then distributed as air coal to various burners.

- The line diagram of a unit system used for Pulverized coal firing is shown in Figure A. Raw coal from bunker is supplied to feeder which receives hot air from air preheater.

- The dried coal from feeder is transferred to pulverising mill where it is crushed to required fineness. The primary air with powdered coal is drawn from pulverising mill by the exhaust fan and it is supplied to the burners in the furnace.

- This system is simple, cheap and easy to control.

Advantages of Unit system :

- It is simple and cheaper than central system.

- Operation and transportation system is simple.

- It allows direct control of combustion from the pulveriser.

- Maintenance charges are less.

- Fans are not subjected to abrasive action of coal dust thus the blade erosion is reduced.

Disadvantages of Unit system :

- Mills operate at variable load on the plant which results in its poor performance.

- The degree of flexibility is less as compared to central system.

- Exhaust fan is subjected to excessive wear since it handles coal dust particles also.

- Failure of any one component of the system results into stoppage of complete operation of system including burners.

2. Central or Bin System :

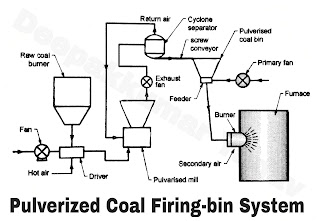

- The diagram of bin system for pulverized coal firing is shown in Figure B.

- The coal is crushed before it is supplied to the raw coal bunker from where it is fed under gravity to drier.

- Preheated hot air is used for drying the coal.

- The dried coal is sent to pulveriser mill.

- Pulverized coal is supplied to a cyclone separator where the transporting air is separated and the required sized coal is transferred to pulverized coal bin with the help of screw conveyor.

- The feeder receives the primary air from a fan and the mixture of pulverized coal and air is supplied to the burners.

- It can supply the pulverized coal continuously even in case of occasional breakdown of coal supply since there is always some coal reserve.

- The pulverizing mill grinds the coal at steady rate irrespective of boiler feed.

- Pulverizing mill size required is less compared to unit system for a given boiler capacity.

- Less operators are needed.

- Power consumption per ton of coal crushed per hour is less.

- There is greater flexibility of operation since the coal and air supply is controlled separately.

- There is no wear and tear of fan since it handles only air.

Disadvantages of Central or Bin System :

- Initial cost of system is high.

- Coal transport system is quite complicated.

- System requires more space.

- Driers are essential.

- It has the possibility of break of fire due to storage of pulverized coal.

- Operation and maintenance cost is higher than unit system.