Co-generation Systems on the Technology Basis

Three types of Co generation System :

- Using steam turbine.

- Using gas turbine.

- Using reciprocating steam turbine

Note : The exhaust steam from the turbine (doing useful work of driving the generator to generate electric energy) is reused in the plant itself to increase the efficiency or can be used in the plant or elsewhere for other purposes.

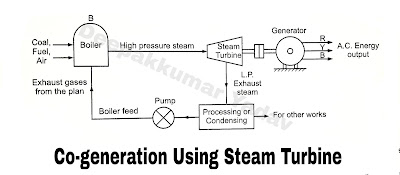

Co-generation Using Steam Turbine

Main equipments are : (1) Boiler, (2) Steam turbine, (3) Exhaust steam condenser, (4) Feed pump.

|

| Figure A |

- Burning of coal in the boiler and heating the water at high pressure steam is produced which is fed to drive steam turbine, in turn it drives the generator to produce electrical energy.

- After doing the useful work, the pressure of steam lowers down and low pressure steam is in the process chamber or condenser.

- It may be taken out and used for other purposes.

- It can be condensed and fed back to the boiler. Efficiency of plant increases.

Advantages of Cogeneration Using Steam Turbine : Less cost, simple, no cooling water needed.

Disadvantages of Cogeneration Using Steam Turbine : Turbine size is large, more civil engineering cost.

Co generation Using Gas Turbine

In this case also exhaust gases having moderate pressure and high temperature can be used for processing and supplied for other useful work. Thus co-generation is achieved. Afterwards the exhaust gases are liberated in the air (open cycle type).

Main Equipments are : (1) Air compressor, (2) Combustion chamber, (3) Gas turbine, (4) Generator, (5) Process consumer, (6) Heat Recovery Boiler (HRB).

|

| Figure B |

Main work : Compressor compresses air goes to combustion chamber where fuel is fed and burn to produce gas at high pressure. This high pressure gas goes to gas turbine which drives the generator to produce electrical energy.

Co-generation-Gas from gas turbine goes to heat recovery boiler (HRB) and this heat is usefully utilized other purposes. Afterwards from HRB the gases are liberated to air.

Advantages of Co generation Using Gas Turbine:

1. Compact small size.

2. Simple design.

3. Any type of hydrogen fuel can be used for combustion

4. Installation work is simple, less time consuming.

Disadvantages of Co generation Using Gas Turbine :

1. Deposition of dirt dust on turbine blades reduced efficiency.

2. Blades of turbine be maintained or to be replaced.

3. Life of system in comparison is less.

Reciprocating Engine Co generation

- One of the types in such co-generation is spark ignition engine.

- Main parts of this system are : (1) Reciprocating engine, (2) Generator, (3) lube oil cooling system, (4) Engine cooling system (5) Heat exchanger, (6) Stack.

- This is generally used in small Stack co-generation plants.

- Input is supplied as air, gas and oil which serves as heat input to the engine.

- Engine is reciprocating compression ignition type.

- Engine shaft is connected to the generator shaft and engine drives the generator which produces electrical energy as an output.

|

| Figure C |