Partial Discharge in Solid Insulation

- The partial discharge (PD) is originated in voids/cavities, cracks or inclusions within a solid dielectric.

- Since the discharge is for only limited portion/area, it is known as partial discharge (PD).

Causes of voids/cavities

- In case of epoxy material, gas-filles voids are caused due to air leaking into mould during curing process.

- Air leakage into mould causes cavity.

- The partial discharge can also occur along the surface of the dielectric.

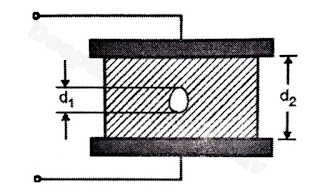

- Consider a dielectric material placed between two electrodes as shown in Figure A.

|

| Figure A |

- When voltage is applied to the dielectric, the voltage stress appearing across the void is significantly higher than the remaining mass of the dielectric.

- This is because the dielectric constant of void is considerably less than surrounding dielectric.

- If the voltage across the void increases above corona inception voltage (CIV) of the gas present in the void, the partial discharge takes place across the void.

- This can cause progressive deterioration of the dielectric material. The equivalent circuit of this process is represented in Figure B.

|

| Figure B |

- CV represents capacitance of void and CY represents capacitance of dielectric in series with void.

- Cb represents capacitance of remaining mass of dielectric.

- When partial discharge takes place, high frequency current are produced for a very short duration of time and after discharge, this current disappears.

- Let applied voltage across the dielectric is V volt and the voltage across void is V1 volt.

d1 = thickness of dielectric

d2 = thickness of dielectric

∈0 = permittivity of void air medium

∈r = permittivity of dielectric medium

∈1 = ∈0 ∈r

|

| Figure C |

V1 = Vd1/d1+ (∈0/

∈1)d2